While CTF is widespread for grain production, its use to enhance grass yields and quality has yet to be widely adopted. Partly this is because it hasn’t been actively promoted but also because the negative impacts of traffic are not always appreciated.

Take the following photos for example. The first pair show a forage harvesting operation and the disparate growth of the grass one week later. The second photo shows the variation in spring growth after winter due to trafficking.

Forage harvesting with modest sized conventional machines (top) and yellowing of the regrowth one week later (bottom), suggesting physical damage to the sward as well as some retarded growth due to compaction.

Variation in spring growth caused by vehicle tracking

Both exhibit the visual impact of traffic which is both direct physical damage to the sward and a reduction in grass growth due to the effects of soil compaction. Research has shown that in the first year of conversion to CTF, dry matter yields can be improved by around 13% in a three-cut forage system. More extensive research over a period of 8 years in a well-established CTF system, albeit with lighter machines, revealed a similar level of yield improvement due to CTF, particularly for the first cut, suggesting the benefit of maintaining CTF from one year to the next.

The economics of production suggested that on a particular farm, a fully integrated CTF system would break even at around 175 ha harvested annually. Above this area, the CTF system is more profitable than conventional practice. Guidance in forage grass can be simple. With high precision steering while grass cutting, tracks are laid out that can be followed visually for raking, harvesting and fertilisation with slurry or mineral fertiliser.

CTF practice in forage grass

CTF in forage grass is most extensively used in Denmark. Contractors often build their CTF service around a 12 m system. In the past, the correct width of mower was the bottleneck but this has now been solved by multiple suppliers.

Some farmers harvest grass in a CTF system with smaller working widths – down to 8 m.

Grass in Denmark is grown in rotation and very seldom as permanent meadow. CTF can keep the grass and especially clover vital for longer. It is a big cost saving if fields can be harvested for 4 years instead of the normal practise of 3 years.

A 12 m CTF system for forage grass in Denmark

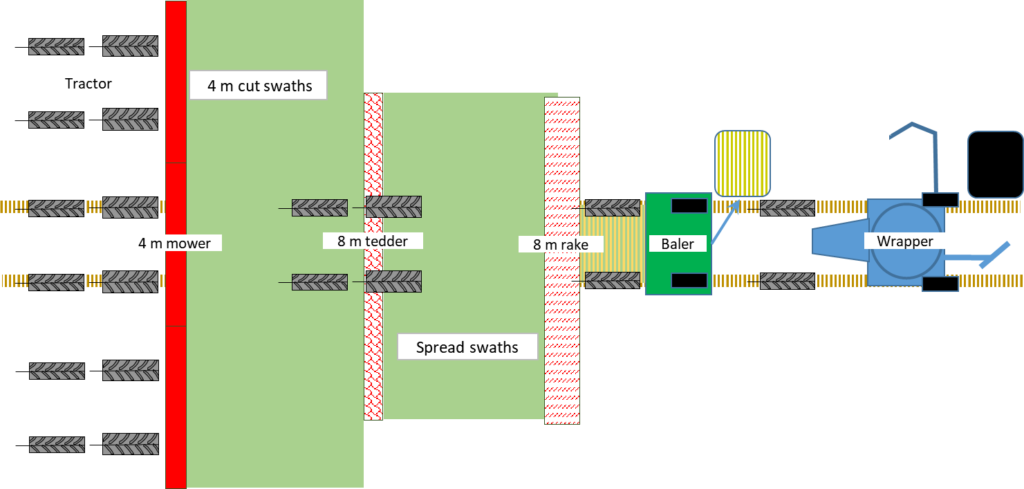

Farmers in Norway are also keen to adopt CTF practices for grass that is cut and baled. The illustration shows that this perfectly feasible with only modest modifications to equipment and more information on this and examples of CTF practices in forage grass will be presented in future newsletters.

Suggested machinery for a 4 m CTF system in grass that is cut, baled and wrapped. The tracked area for this system is around 26%.

If you want to hear from a farmer practising CTF in forage grass, note the date of our next conference at Harper Adams University (UK) which will be on Wednesday 3rd December 2025 – both in-person and online.

No responses yet